Vertical Coolant Filter For CNC Machine Tool Coolant Tank Cleaning

Product Details:

| Place of Origin: | China |

| Brand Name: | Diang Tianke |

| Certification: | ISO CE |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Sets |

|---|---|

| Price: | Negotiable |

| Packaging Details: | PP bag inside Carton |

| Delivery Time: | 7-15 workdays |

| Payment Terms: | LC, T/T, PayPal, Western Union, Small-amount payment, Money Gram |

|

Detail Information |

|||

| Model NO.: | Datk-qz | Installation: | Horizontal |

|---|---|---|---|

| Centrifuge Type: | Horizontal Spiral Centrifuge | Distillation Equipment Type: | Steam Distillation Equipment |

| Extraction Tower Type: | Vibration Plate Tower | Pressure: | High Pressure |

| Condition: | New | Weight: | 78kg |

| Processing Capacity: | 8000L | Working Air Pressure: | 0.4-0.6MPa |

| Air Consumption: | 0.6m³/Min Max | Filtration: | 0.75mm |

| Transport Package: | Wooden Case | Specification: | 850*450*900mm |

| Trademark: | Datk | Origin: | China |

| HS Code: | 8401200000 | Supply Ability: | 5000 Units/Year |

| After-sales Service: | Life | Warranty: | One Year |

| Type: | Centrifuge | Object: | Cosmetic |

| Separation Mode: | Filter Type | Operating Type: | Continuous Type |

| Highlight: | Vertical Coolant Filter For CNC Machine,Machine Tool Coolant Tank Cleaning,Coolant Filter For CNC Machine Tool |

||

Product Description

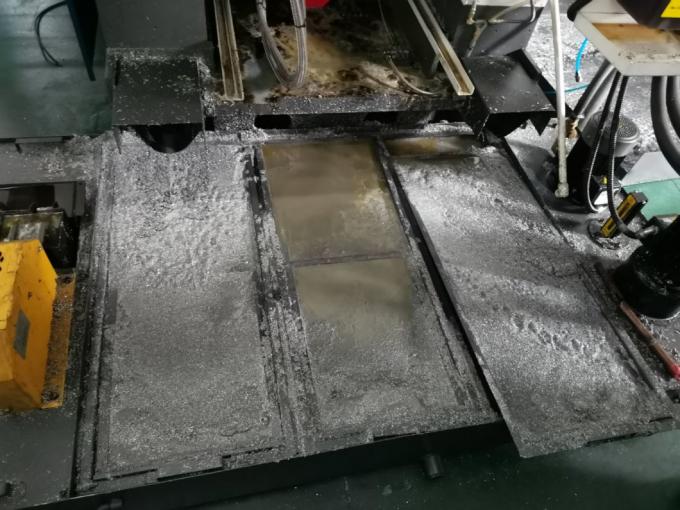

Vertical Machine Tool Coolant Tank Cleaning, Only Requires Air Connection, High Efficiency

Product Description

The cutting fluid slag cleaning and changing machine replaces manual slag cleaning, and its powerful slag cleaning function saves a lot of time and manpower for enterprises, avoiding allergic reactions caused by workers coming into contact with cutting fluid due to slag cleaning. The equipment has high work efficiency, pure pneumatic, simple and convenient operation, one click start, and zero consumables.

| Product size | 850*450*900mm |

| Equipment weight | 78kg |

| Working air pressure | 0.4-0.6MPa |

| Filtration | 0.75mm |

| Processing capacity | 7000-8000L/h |

The slag cleaning and liquid changing machine is a cutting fluid purification treatment equipment independently developed and designed by our company, with zero consumables and stable performance; Small and flexible equipment; Quick effect in 55 seconds; 24-hour online processing, efficient and convenient; Built in pneumatic diaphragm pump, no need to plug in, connected to compressed air to work. After years of research and development, testing and improvement, it has become a very mature product without the need for installation and debugging. The equipment is strictly produced in accordance with the requirements of the ISO9001 quality management system, with guaranteed quality.