Aluminum Chip Cleaning CNC Coolant Filter System Coolant Tank Cleaner

Product Details:

| Place of Origin: | China |

| Brand Name: | Diang Tianke |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | WOODEN CASE |

| Delivery Time: | 7-15 workdays |

| Payment Terms: | LC, T/T, PayPal, Western Union, Small-amount payment, Money Gram |

| Supply Ability: | 1 pis |

|

Detail Information |

|||

| Installation: | Horizontal | Centrifuge Type: | Horizontal Spiral Centrifuge |

|---|---|---|---|

| Distillation Equipment Type: | Steam Distillation Equipment | Extraction Tower Type: | Vibration Plate Tower |

| Pressure: | High Pressure | Weight: | 78kg |

| Processing Capacity: | 8000L | Working Air Pressure: | 0.4-0.6MPa |

| Air Consumption: | 0.6m³/Min Max | Filtration: | 0.75mm |

| Transport Package: | Wooden Case | Specification: | 850*450*900mm |

| Trademark: | Datk | HS Code: | 8401200000 |

| Supply Ability: | 5000 Units/Year | After-sales Service: | Life |

| Warranty: | One Year | Type: | Centrifuge |

| Object: | Cosmetic | Separation Mode: | Filter Type |

| Operating Type: | Continuous Type | Application: | Metal Processing Industry |

| Frequency: | 50Hz | Function: | Remove Sludge And Chips From Metal Cutting Machines |

| Material: | Stainless Steel | Model: | CSRM-100 |

| Operation Mode: | Automatic | Power: | 2.5kW |

| Power Source: | Electric | Size: | 1200mm*800mm*1500mm |

| Voltage: | 220V | ||

| Highlight: | Aluminum Chip Cleaning CNC,Aluminum Chip CNC Coolant Filter System,coolant tank cleaner CNC |

||

Product Description

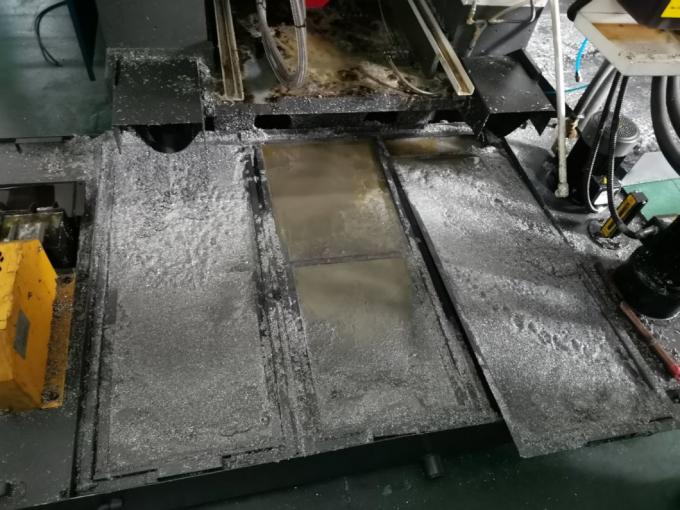

Cleaning of the cooling liquid tank of CNC machine tools, cleaning of aluminum and iron filings, with a filtration accuracy of 0.75mm

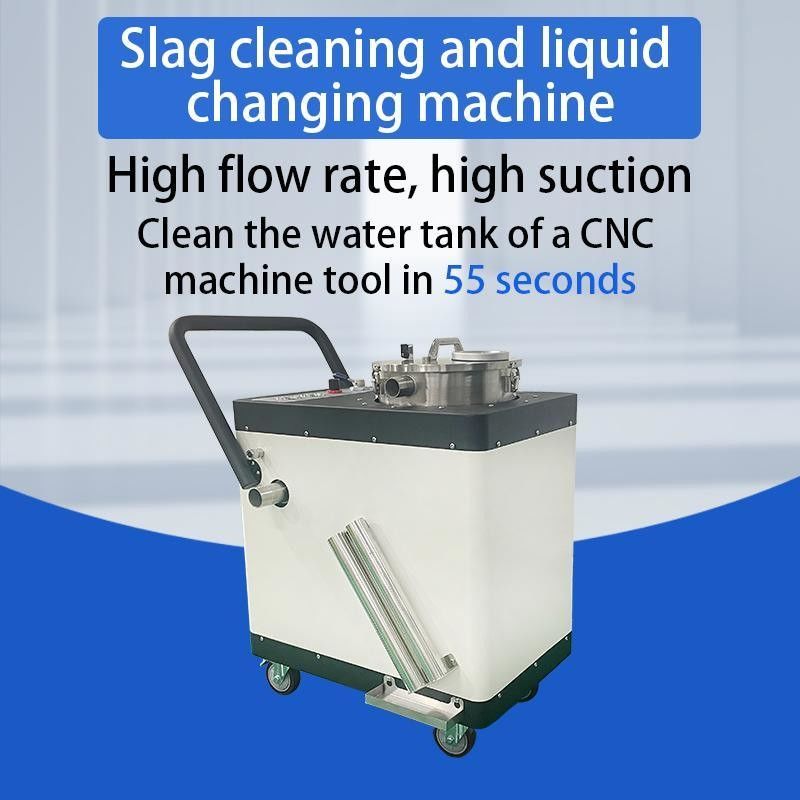

CNC Aluminum Chip Cleaning Machine Has a Large Amount of Slag Cleaning and Liquid Exchange Processing

Since its establishment, Guangzhou Di'angtianke Automation Equipment Co., Ltd. has been committed to solving the problem of "waste liquid and slag" caused by industrial processes for customers in the metal processing field. The company has a skilled and professional research and development team, dedicated to providing environmentally friendly purification products to domestic and foreign customers. The company provides personalized services and provides solutions based on the on-site processing volume of customers.

Two main functions:

Slag cleaning: used to clean metal debris, oil sludge, and other impurities in the liquid tank of the machining center machine tool

Fluid exchange: can be used as a transfer pump for extracting and transferring water-based cutting fluid, water-based cleaning agents, and other liquids

| Product size | 850*450*900mm |

| Equipment weight | 78kg |

| Working air pressure | 0.4-0.6MPa |

| Filtration | 0.75mm |

| Processing capacity | 7000-8000L/h |

The slag cleaning and liquid changing machine is a cutting fluid purification treatment equipment independently developed and designed by our company, with zero consumables and stable performance; Small and flexible equipment; Quick effect in 55 seconds; 24-hour online processing, efficient and convenient; Built in pneumatic diaphragm pump, no need to plug in, connected to compressed air to work. After years of research and development, testing and improvement, it has become a very mature product without the need for installation and debugging. The equipment is strictly produced in accordance with the requirements of the ISO9001 quality management system, with guaranteed quality.

A large capacity stainless steel filter barrel that can filter a large amount of residue at once. You can customize different levels of filtration accuracy according to actual needs to optimize the utilization rate of cutting fluid. Our customers are located throughout the country and Southeast Asia, with mature process technology and rich experience in cutting fluid treatment, allowing customers to buy comfortably and use with peace of mind!